Waterproof

Waterproof

Mardom Decor mouldings are fully waterproof. This means that they can be successfully used in rooms with high humidity, such as bathrooms or kitchens.

Resistant to UV rays

Resistant to UV rays

Thanks to special refinements and coatings, mouldings are resistant to UV radiation. Installation of mouldings in a sunny place will not cause yellowing or discolouration.

Primed and Paintable

Primed and Paintable

The mouldings are factory-coated with a special primer with smoothing, protecting properties that facilitate the distribution of subsequent layers of paint. For a perfect visual effect, we recommend painting the mouldings with any water paint after installation.

Swelling resistance and durability

Swelling resistance and durability

Mardom Decor mouldings, unlike MDF products, do not undergo deformation, delamination and swelling under the influence of moisture. These mouldings are also impact resistance, which adds to their durability.

Durable material

Durable material

The product is made of PolyForce material using the innovative ScratchShield technology, which features increased impact strength and impact resistance.

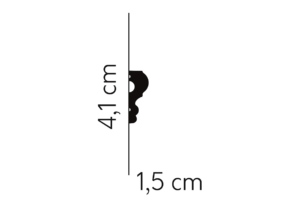

Installation

Installation

Surface preparation is key! First, make sure that the surface is dry and dust-free. Use a mitre saw or hand saw to cut the mouldings. With a sealant gun, apply glue on the length of the moulding. At Noble, we offer installation of mouldings, but if you wish to do installation yourself, you can rent the mitre box at our store.

Recommended adhesive

Recommended adhesive

Use the Mardom Decor Fix Pro adhesive for a long-lasting seal between the mouldings and the surface. One tube is enough for installation of about 8 metres of mouldings. Use the Flex Filler to fill the joints between mouldings. This filler is resistant to moisture, easy to apply and sand and prevents cracks from forming.

Installation

Installation Recommended adhesive

Recommended adhesive